Hot Oil Treatment

Durable outdoor wood, treated with linseed oil

This process uses hot linseed oil as an after treatment of traditional biocide treated timber used for siding and other outdoor uses.

With added pigment, the process results in a ready to use product which is exceptionally dimensionally stable and will not require any after treatment (painting) for 5 – 25 years, depending on the actual climatic conditions.

After high pressure impregnation, the moisture content is high.

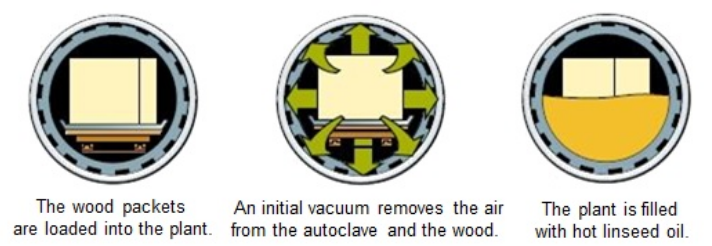

The treated wood is taken directly from the impregnation autoclave to the hot-oil autoclave, where it is dried down during 6-8 hours to a ready to use product with 14-16 % moisture.

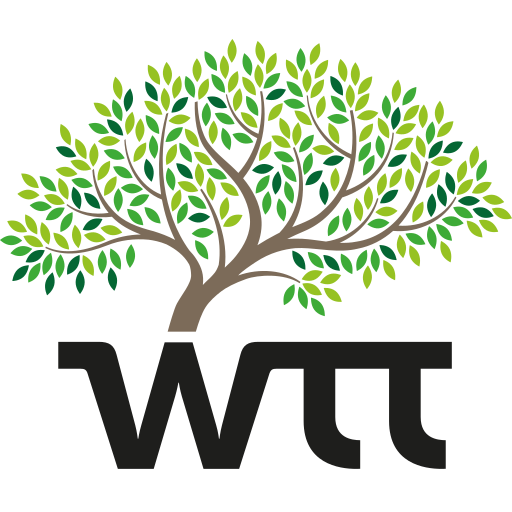

At the end of the process, the 1-2 mm penetration of linseed oil into the wood creates an envelope which effectively seals the surface of the wood. This reduces the fluctuation of the wood moisture content during the seasons significantly, thus giving the wood exceptional dimensional stability.

WTT has more than 20 years of experience with this value adding niche product. In the later years it has seen significant growth primarily on the Scandinavian markets, with reported annual growth rates of 30 %. UK and Central European markets are also developing. WTT supplies full automatic plants to several treating companies in this high value wood product niche.

CAPACITY

9 m³ / charge

END USE

Siding and other outdoor uses

WOOD SPECIES

Both hard- and softwoods

DURABILITY OF WOOD

Durability of wood – 5-25 years

Primer oil treated cladding wood

Hot-oil impregnation provides a more durable wood

The below graph shows the moisture contents in Primer Oil treated cladding wood in comparison with untreated wood in outdoor conditions. The changes in moisture content caused by varying weather conditions are significantly reduced in the Primer Oil treated wood. This leads to a pronounced reduction in the traditional fluctuations in the wood and to less cracks overtime.

Process steps of hot oil impregnation